CUTTING EDGE PERFECTION, FASHIONED FOR YOUR NEEDS, ENGINEERED BY ELLSWORTH

Simply order what you need and have the confidence it will exceed expectations.

Contact Us

The leading manufacturer of application specific cutting tools

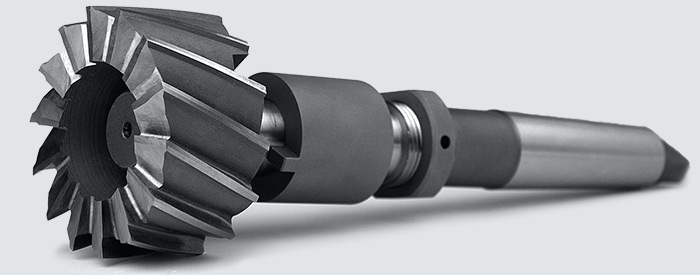

Custom Cutting Tools & Tooling

Being family owned, ECT has been able to use the past four decades to establish an unparalleled dominance in Southeastern MI. Now, Ellsworth Cutting Tools the preeminent manufacture of application specific cutting tools. Not limited to the cutting tools themselves we have applied our paradigm shattering design prowess to fixturing, bushings, work holdings, tool holders, and fabrication. Setting the bar for whatever products we sink our teeth into.

Made entirely here in the USA we sharpen our focus to improve upon your tools. Never ceasing until our customers are content. With over 200 years of combined cutting tool experience, the pursuit to improve upon perfection is paramount to our continued story of success.

We design to your needs

How can we help you?

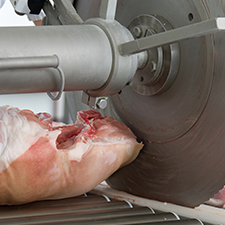

Our expertise spans all industry applications. From component assembly to OEM field repairs we will work with you to put the best tools in the hands of your operators. Our obsessive attention to detail allows for tool designs that become the industry standard. We know this by the endless repeat business we’ve generated to date. Call or email today to see how we can help you increase efficiency and improve the quality of your parts.

Ellsworth Industry Solutions

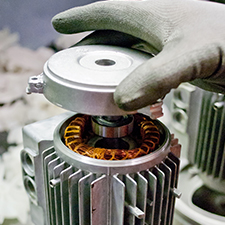

Aerospace

High quality HSS, HSCO, & Carbide Drills/Reamers & Fabricated Assembly Tooling.

More Information

Shipyard, Military & defense

Fleet Maintenance & Repair Kits, Manual Specified Special Cutters.

More Information

Heat Exchanger

Specialty Tube & De-bur Tools, Precision Coolant Fed Drills & Reamers, & Clean-Out Tools.

More Information

Mining & Oil Drilling

Fabricated Large Diameter/Extra-Length Tools & Cutting Heads in Tubular & Solid Sections.

More Information

Rail & Heavy Equipment

Repair Reamers, Arbor Style Cutters, & Heavy Duty Chamfering Bits.

More Information

Contact Us

We are happy to answer any questions about our products and service, or to schedule a presentation.

(586) 598-6040

sales@ectmi.com

Our Story

Ellsworth Cutting Tools was engineered in 1980 as the brainchild of habitual inventor Ellsworth Miller III. Always uncompromising, he found the “one-size fits all” approach to “standard” and “special” cutting tools beyond dull. Unable to cut into projects as freely as one of his tools, he spent much of his time refining many processes while working for other manufactures. Finally, fed up with convention and driving for new, innovative, and transformative cutting tool designs he established a company that mirrored his own dedication to innovation. As opportunities arose, customers came to rely on the true value of the tools: Turning High Speed Steel and Carbide into GOLD. The prime design principle is to evolve beyond perfection, resulting in the most reliable, cost-effective, high quality holes, and material removal in the business. The next step was ensuring his workforce embodied the same uncompromising quality he insisted upon in his tools. So he hand selected the finest craftsmen to mentor, imparting a methodology: “Know why, not just how”. All of our cutting tool master-craftsmen know the “why” i.e., the purpose behind all of the geometry, tolerances, and features of a tool. To this day, the select few chosen to uphold the craft are striving to improve upon perfection. Being raised in the mold of his father, his son Ellsworth Miller IV and 25 year business veteran Douglas Baditoi carry on the imperative: Evolve beyond perfection. Following these principles, new capital investments in capacity continue to be made by expanding to 13,000 square feet of custom machine tools, and the latest production equipment.